| |

E

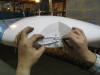

Here I am driving the rivets Nora is bucking. (2/26/04) E

Here I am driving the rivets Nora is bucking. (2/26/04) |

| |

F

The weekend of March 21st, 22nd, & 23rd, 2004 Doug Sytsma, my

collage roommate, A&P, and Northwest Airlines Maintenance

Manager came down from Detroit to lend a hand pounding rivets.

In two days we finished riveting the left wing and started on

the right wing. (03/20/04) F

The weekend of March 21st, 22nd, & 23rd, 2004 Doug Sytsma, my

collage roommate, A&P, and Northwest Airlines Maintenance

Manager came down from Detroit to lend a hand pounding rivets.

In two days we finished riveting the left wing and started on

the right wing. (03/20/04) |

| |

E

Here it the left wing off the jig for the first time.

()3/20/04) E

Here it the left wing off the jig for the first time.

()3/20/04) |

| |

F

We even managed to assemble and match drill the right wing

during Doug's visit. Now all that is left is deburring,

dimpling, priming, and riveting. (03/21/04) F

We even managed to assemble and match drill the right wing

during Doug's visit. Now all that is left is deburring,

dimpling, priming, and riveting. (03/21/04) |

| |

E

After a long delay, Nora's Father came by on 07/31/04 to help

buck rivets on the leading edge and top skins of the right

wing. (Sorry no pictures) On August 14th John

Wigney, Europa builder and now flier, came by on short notice

to help me finish riveting the top skins on the right wing.

(08/14/04) E

After a long delay, Nora's Father came by on 07/31/04 to help

buck rivets on the leading edge and top skins of the right

wing. (Sorry no pictures) On August 14th John

Wigney, Europa builder and now flier, came by on short notice

to help me finish riveting the top skins on the right wing.

(08/14/04) |

| |

F

Four hours later John helped me lift the wing off the jig and

place it on the cradle. After John left I celebrated by

taking down the wing jig and cleaning the place up. Next

week I order the fuselage kit. (08/14/04) F

Four hours later John helped me lift the wing off the jig and

place it on the cradle. After John left I celebrated by

taking down the wing jig and cleaning the place up. Next

week I order the fuselage kit. (08/14/04) |

| |

E

Six days before the wedding and here is Nora helping rivet the

bottom skin on the right wing. At least she can't say

she didn't know what she was getting herself into. (09/06/04) E

Six days before the wedding and here is Nora helping rivet the

bottom skin on the right wing. At least she can't say

she didn't know what she was getting herself into. (09/06/04) |

| |

F

Last weekend

was spent cutting the left wing skin and fitting the Gretz

pitot tube mast, which is supposed to hold the Dynon pitot

tube. This pitot tube is configured to feed AOA information

to my future Dynon EFIS system. After cutting the wing skin,

drilling holes for the AOA line, etc. I test fitted the mast

and all looked good until I slid the pitot tube down the mast

and found the pre-drilled holes in the mast that are to hold

the pitot in place wouldn't leave any room for proper edge

distance on the pitot tube. I'm currently talking to both

Dynon and Warren Gretz about a solution. BTW, both the Gretz

mount and the Dynon unit seem to be top quality items and I do

expect there will be an easy resolution. (I smudged the

chrome pitot tube bracket so the flash wouldn't wash it out

.) (09/25/04) F

Last weekend

was spent cutting the left wing skin and fitting the Gretz

pitot tube mast, which is supposed to hold the Dynon pitot

tube. This pitot tube is configured to feed AOA information

to my future Dynon EFIS system. After cutting the wing skin,

drilling holes for the AOA line, etc. I test fitted the mast

and all looked good until I slid the pitot tube down the mast

and found the pre-drilled holes in the mast that are to hold

the pitot in place wouldn't leave any room for proper edge

distance on the pitot tube. I'm currently talking to both

Dynon and Warren Gretz about a solution. BTW, both the Gretz

mount and the Dynon unit seem to be top quality items and I do

expect there will be an easy resolution. (I smudged the

chrome pitot tube bracket so the flash wouldn't wash it out

.) (09/25/04) |

| |

E

It has been a while since I've worked on the plane. Nora

and I were still wrapping up wedding commitments which has

left no time for other things. Anyway, I finally had a

chance to test fit the pitot tube. (The tape is to keep

bugs from taking up residence in the pitot system until it is

actually used.) (10/26/04) E

It has been a while since I've worked on the plane. Nora

and I were still wrapping up wedding commitments which has

left no time for other things. Anyway, I finally had a

chance to test fit the pitot tube. (The tape is to keep

bugs from taking up residence in the pitot system until it is

actually used.) (10/26/04) |

| |

F

One other reason for the delay was the Dynon pitot tube had to

be modified by filing down the neck so it would fit into the

Gretz mount far enough that the #6 screws used to secure it

would have enough edge space. Some careful work on the

belt sander, followed by hand filing did the trick.

(10/26/04) F

One other reason for the delay was the Dynon pitot tube had to

be modified by filing down the neck so it would fit into the

Gretz mount far enough that the #6 screws used to secure it

would have enough edge space. Some careful work on the

belt sander, followed by hand filing did the trick.

(10/26/04) |

| |

E

Here

is how the pitot tube and AOA lines will look inside the

wing. They will be tie-wrapped to the black wire conduit at

the top of the picture. Remember, the aileron push tube has

to go occupy this space as well as the lines. The pink string

will remain in place in case I ever wish to install a heated

pitot tube and need to pull a wire for it. E

Here

is how the pitot tube and AOA lines will look inside the

wing. They will be tie-wrapped to the black wire conduit at

the top of the picture. Remember, the aileron push tube has

to go occupy this space as well as the lines. The pink string

will remain in place in case I ever wish to install a heated

pitot tube and need to pull a wire for it.

Update: July 15, 2007

E After

installing the wings, pitot, etc. at the airport and after the

VFR transponder and pitot/static check I found the connections

above leaked like the Titanic. On the advice of the

Avionics Technician who inspected my plane, I changed the

connection by cutting off the AN fittings and removed the

quick connect. I suspect it was the "quick

connect" that leaked, not the AN fitting. They were

replaced with a section of vacuum hose and some tie wraps.

E After

installing the wings, pitot, etc. at the airport and after the

VFR transponder and pitot/static check I found the connections

above leaked like the Titanic. On the advice of the

Avionics Technician who inspected my plane, I changed the

connection by cutting off the AN fittings and removed the

quick connect. I suspect it was the "quick

connect" that leaked, not the AN fitting. They were

replaced with a section of vacuum hose and some tie wraps. |

| |

F

Every married builder soon realizes that at some point in the

project their wonderful and understanding wife asks for a

favor. It is at that point the builder had better jump on it,

get it done, and make the wife happy so they can get back to

building. My little task was to finish carpeting a cat tree

that I had built some time before. The problem was where I

should store the flaps while I work on the cat tree. It

dawned on me I could build a rack on the wing cradle to hold

and protect them. (2/13/05) F

Every married builder soon realizes that at some point in the

project their wonderful and understanding wife asks for a

favor. It is at that point the builder had better jump on it,

get it done, and make the wife happy so they can get back to

building. My little task was to finish carpeting a cat tree

that I had built some time before. The problem was where I

should store the flaps while I work on the cat tree. It

dawned on me I could build a rack on the wing cradle to hold

and protect them. (2/13/05) |

| |

E

I finally got around to plugging the hole I drilled in the

bottom of the left wing for Van's pitot tube. I drew a

circle on scrape aluminum I had laying around, in my case it

was the disks I cut out of the VS stiffener for the lightening

holes. After drilling a center hole and countersinking

it for the rivet I cut, sanded, and filed the plug until it

fit in the hole. The rivets on either side of the pitot

tube hole were drilled out and a strap made from some scrap

064 aluminum was cut to bridge the three holes. The

strap was riveted in place leaving a pocket where the pitot

tube was supposed to go. E

I finally got around to plugging the hole I drilled in the

bottom of the left wing for Van's pitot tube. I drew a

circle on scrape aluminum I had laying around, in my case it

was the disks I cut out of the VS stiffener for the lightening

holes. After drilling a center hole and countersinking

it for the rivet I cut, sanded, and filed the plug until it

fit in the hole. The rivets on either side of the pitot

tube hole were drilled out and a strap made from some scrap

064 aluminum was cut to bridge the three holes. The

strap was riveted in place leaving a pocket where the pitot

tube was supposed to go.

E

The plug was put in the hole and matched drilled to the newly

installed strap and riveted in place. E

The plug was put in the hole and matched drilled to the newly

installed strap and riveted in place.

E Here is the finished

product. Not too bad but I sure wish I knew I was going to

use the Dynon pitot before I followed the instructions and

drilled out that hole (4/14/05) |

| |

F

My in-laws came and spent Labor day weekend with us and

between going to the fantastic NC Zoo and other obligations we

managed to find time to rivet the bottom skin on the left

wing. The pitot tube is ready to install but was left

off to keep it from getting damaged. (9/4/05) F

My in-laws came and spent Labor day weekend with us and

between going to the fantastic NC Zoo and other obligations we

managed to find time to rivet the bottom skin on the left

wing. The pitot tube is ready to install but was left

off to keep it from getting damaged. (9/4/05) |

| |

E

Fitting the wing tips isn't that difficult. The trick is

to measure the recesses and cut them to fit. The

dimensions are listed on one of the drawings and I'm too lazy

to walk back to the basement to find out which drawing.

I used a cutoff wheel in my Dremel and it worked great.

I'm sure there are other ways to cut the fiberglass but this

method was recommended to me and it worked. (11/15/05) E

Fitting the wing tips isn't that difficult. The trick is

to measure the recesses and cut them to fit. The

dimensions are listed on one of the drawings and I'm too lazy

to walk back to the basement to find out which drawing.

I used a cutoff wheel in my Dremel and it worked great.

I'm sure there are other ways to cut the fiberglass but this

method was recommended to me and it worked. (11/15/05) |

| |

F

Next up was fitting the the wing tip ribs. Don't forget

the to flute them. (11/15/05) F

Next up was fitting the the wing tip ribs. Don't forget

the to flute them. (11/15/05) |

| |

E

After you figured out the correct location for the ribs, mark

the rivet lines on the wing tips, measure and drill the rivet

holes. I did this in a two step process, similar to

drilling the "J" channels. First I drilled the holes,

then marked the center of the rib flanges, lined them up and

drilled them, clecoing as I went along. (11/15/05) E

After you figured out the correct location for the ribs, mark

the rivet lines on the wing tips, measure and drill the rivet

holes. I did this in a two step process, similar to

drilling the "J" channels. First I drilled the holes,

then marked the center of the rib flanges, lined them up and

drilled them, clecoing as I went along. (11/15/05) |

| |

F

The final step was to set the aileron to the correct position.

Remember the aileron alignment tool you made last year?

Time to dust it off. After aligning the aileron I used a

spring clamp between the aileron and the flap to hold it in

place. Since my flaps are in perfect alignment yet they

had to be lowered to match up with the aileron. With the

aileron locked in place, I lined up the wing tip, taped it in

place, and drilled it to the wing. (11/15/05) F

The final step was to set the aileron to the correct position.

Remember the aileron alignment tool you made last year?

Time to dust it off. After aligning the aileron I used a

spring clamp between the aileron and the flap to hold it in

place. Since my flaps are in perfect alignment yet they

had to be lowered to match up with the aileron. With the

aileron locked in place, I lined up the wing tip, taped it in

place, and drilled it to the wing. (11/15/05) |

| |

E

Fitting the lens covers is easy enough, even if a bit time

consuming. They come as one unit and need to be cut in

half. There are some dimples from the molding process.

Just connect the dots and cut along the line. There is

enough extra that will still require trimming you don't have

to worry about the this cut. (11/23/05) E

Fitting the lens covers is easy enough, even if a bit time

consuming. They come as one unit and need to be cut in

half. There are some dimples from the molding process.

Just connect the dots and cut along the line. There is

enough extra that will still require trimming you don't have

to worry about the this cut. (11/23/05) |

| |

F

I used my Dremel with 426 reinforced cutoff wheels to cut the

fiberglass wing tips and the lens covers. Do not use

regular cutoff Dremel cutoff wheels, they tend to break off

the arbor and go shooting across your shop. I was lucky

and was never hit by one of those flying wheels. (11/23/05) F

I used my Dremel with 426 reinforced cutoff wheels to cut the

fiberglass wing tips and the lens covers. Do not use

regular cutoff Dremel cutoff wheels, they tend to break off

the arbor and go shooting across your shop. I was lucky

and was never hit by one of those flying wheels. (11/23/05) |

| |

E

Here is the first trial fit of the lens cover, as you can see,

there is a good bit to trim. (11/23/05) E

Here is the first trial fit of the lens cover, as you can see,

there is a good bit to trim. (11/23/05) |

| |

F

The lens has a small lip as result of the molding process.

This needs to be trimmed. Be careful not to slip with

the Dremel or you will be buying a new lens. (11/23/05) F

The lens has a small lip as result of the molding process.

This needs to be trimmed. Be careful not to slip with

the Dremel or you will be buying a new lens. (11/23/05) |

| |

E

After cutting the lens the edge has to be "dressed" to keep it

from cracking. The scraper in the left most picture is

from Avery's and works well for removing the bigger "boogers"

left over from trimming. I used 120 grit sandpaper in

the belt sander and used this to finish "dress" the Plexiglas

lens. (11/23/05) E

After cutting the lens the edge has to be "dressed" to keep it

from cracking. The scraper in the left most picture is

from Avery's and works well for removing the bigger "boogers"

left over from trimming. I used 120 grit sandpaper in

the belt sander and used this to finish "dress" the Plexiglas

lens. (11/23/05) |

| |

F

After trimming, tape the cover in place and mark it for final

trimming. You might have to repeat this process a few

times until you get a "perfect" (good enough?) fit. (11/23/05) F

After trimming, tape the cover in place and mark it for final

trimming. You might have to repeat this process a few

times until you get a "perfect" (good enough?) fit. (11/23/05) |

| |

E

After trimming, tape the cover in place and mark it for final

trimming. You might have to repeat this process a few

times until you get a "perfect" (good enough?) fit. (11/23/05) E

After trimming, tape the cover in place and mark it for final

trimming. You might have to repeat this process a few

times until you get a "perfect" (good enough?) fit. (11/23/05) |

| |

F

Once the lens is properly fitted, tape it in place, mark the

location for the screw and drill a hole on the top and one on

the bottom. Make sure you use drill bits designed for

Plexiglas. (11/23/05) F

Once the lens is properly fitted, tape it in place, mark the

location for the screw and drill a hole on the top and one on

the bottom. Make sure you use drill bits designed for

Plexiglas. (11/23/05) |

| |

E

Once drilled, the lens may be clecoed in place. Next up

will be countersinking the holes for machine screws and

installing the platenuts in the wing tip. (11/23/05) E

Once drilled, the lens may be clecoed in place. Next up

will be countersinking the holes for machine screws and

installing the platenuts in the wing tip. (11/23/05) |

| |

F

Installing the the position /

strobe lights on the wing tip was fairly straight forward.

First up was taking a look at the lights. I went with

Airplane

Gear's Skybright Strobes & Lights and was surprised at how

bright the lights are. Of course, I still need to add

the wiring and try out the strobes but if they are half as

bright as the position lights my little RV-9 will be light up

like a 747. These lights use fewer LED's than some other

product available for the homebuilt market but they make up

for that by using a reflector to improve the light dispersion. (11/26/05) F

Installing the the position /

strobe lights on the wing tip was fairly straight forward.

First up was taking a look at the lights. I went with

Airplane

Gear's Skybright Strobes & Lights and was surprised at how

bright the lights are. Of course, I still need to add

the wiring and try out the strobes but if they are half as

bright as the position lights my little RV-9 will be light up

like a 747. These lights use fewer LED's than some other

product available for the homebuilt market but they make up

for that by using a reflector to improve the light dispersion. (11/26/05) |

| |

E

The first thing I did was to make sure the wing was level.

Then I drew a "level" line in the cut out for the light.

The parting line on the fiberglass tips from Van's are close

to level but not exact. (11/26/05) E

The first thing I did was to make sure the wing was level.

Then I drew a "level" line in the cut out for the light.

The parting line on the fiberglass tips from Van's are close

to level but not exact. (11/26/05) |

| |

F

Next up, disassemble the lights. Since the cutout in the

RV wingtip would shield an aft facing white light I ordered

these lights w/o the white tail light. There is a

separate white tail light / strobe that is fitted to the

rudder bottom on the new RV kits. (11/26/05) F

Next up, disassemble the lights. Since the cutout in the

RV wingtip would shield an aft facing white light I ordered

these lights w/o the white tail light. There is a

separate white tail light / strobe that is fitted to the

rudder bottom on the new RV kits. (11/26/05) |

| |

E

The bottom plate of the light fixtures has a threaded brass

insert to hold the unit together. Using a drill bit that

just fits inside the brass fitting line up the backing plate

and turn the drill bit by hand just enough to mark the line.

Take down the plage and finish drill the hole with a power

drill. (11/26/05) E

The bottom plate of the light fixtures has a threaded brass

insert to hold the unit together. Using a drill bit that

just fits inside the brass fitting line up the backing plate

and turn the drill bit by hand just enough to mark the line.

Take down the plage and finish drill the hole with a power

drill. (11/26/05) |

| |

F

With the aft screw inserted to hold the plate in place lined

it up with the level line and turn the drill bit by hand to

mark the location of the second hole. As before, remove

the backing plate and finish drill the hole. To allow

the room for the bolts, enlarge both holes with a #40 drill

bit. (11/26/05) F

With the aft screw inserted to hold the plate in place lined

it up with the level line and turn the drill bit by hand to

mark the location of the second hole. As before, remove

the backing plate and finish drill the hole. To allow

the room for the bolts, enlarge both holes with a #40 drill

bit. (11/26/05) |

| |

E

Once both bolt holes are drilled reinstall the the plate and

mark the wire hole. Remove the plate, and drill the wire

hole to size using a uni-bit. (11/26/05) E

Once both bolt holes are drilled reinstall the the plate and

mark the wire hole. Remove the plate, and drill the wire

hole to size using a uni-bit. (11/26/05) |

| |

F

After fitting and installing the first light, the results were

very pleasing. It wasn't until the lens over was fitted

that we realized the LED's and their reflector stuck out too

far and interfered with the cover. The solution was

fairly straight forward. Since this light did not

include the rear white lights, the section aft of the rear

bolt hole could be cut off w/o impact the function of the

light / strobe fixture. A few seconds on the band saw,

new holes were drilled and the light was installed. (11/26/05) F

After fitting and installing the first light, the results were

very pleasing. It wasn't until the lens over was fitted

that we realized the LED's and their reflector stuck out too

far and interfered with the cover. The solution was

fairly straight forward. Since this light did not

include the rear white lights, the section aft of the rear

bolt hole could be cut off w/o impact the function of the

light / strobe fixture. A few seconds on the band saw,

new holes were drilled and the light was installed. (11/26/05) |

| |

E

Here is the final product. The entire installation took

less than an hour for both wings, including inspecting and

cutting the light after discovering the interference with the

initial fit. (11/26/05) E

Here is the final product. The entire installation took

less than an hour for both wings, including inspecting and

cutting the light after discovering the interference with the

initial fit. (11/26/05) |

| |

F

Start fitting the Wing Root Fairings (WRF) by marking them

left and right. They are identical parts right up until

you match drill them. (12/10/05) F

Start fitting the Wing Root Fairings (WRF) by marking them

left and right. They are identical parts right up until

you match drill them. (12/10/05) |

| |

E

Remove the top and bottom inboard wing tank screws.

These screws will secure the WRF as well as the tank. (12/10/05) E

Remove the top and bottom inboard wing tank screws.

These screws will secure the WRF as well as the tank. (12/10/05) |

| |

F

Drill, deburr, and dimple the two holes shown in this picture.

Remember to set the dimples in opposite directions on the left

and right WRF. These pictures are from the left WRF.

The inboard tank screws will go through these holes. (12/10/05) F

Drill, deburr, and dimple the two holes shown in this picture.

Remember to set the dimples in opposite directions on the left

and right WRF. These pictures are from the left WRF.

The inboard tank screws will go through these holes. (12/10/05) |

| |

E

Cleco the WRF in place and install the two fuel tank screws.

Use a thin strip of something (wood is what I used) to set the

edge distance as the WRF wraps around the fuel tank. (12/10/05) E

Cleco the WRF in place and install the two fuel tank screws.

Use a thin strip of something (wood is what I used) to set the

edge distance as the WRF wraps around the fuel tank. (12/10/05) |

| |

F

Prior to match drilling the holes in the fuel tank skins, mark

them with Sharpie, remove the WRF and check for edge distance.

The kit was so good that I did not have an edge distance

problem so I reinstalled the WRF and match drilled it with a

#40 drill bit. Once all the holes are match drilled I

removed the WRF, enlarged, deburred, and dimpled the holes in

them. When the wings are moved in a few weeks I will

enlarged the those holes and install plate nuts. It took

me awhile to figure this out but the holes on the top of the

wing where the wing walk doublers are get counter sunk and

thus use K1000 plate nuts. All the other holes are

dimpled and use K1100 plate nuts. (12/10/05) F

Prior to match drilling the holes in the fuel tank skins, mark

them with Sharpie, remove the WRF and check for edge distance.

The kit was so good that I did not have an edge distance

problem so I reinstalled the WRF and match drilled it with a

#40 drill bit. Once all the holes are match drilled I

removed the WRF, enlarged, deburred, and dimpled the holes in

them. When the wings are moved in a few weeks I will

enlarged the those holes and install plate nuts. It took

me awhile to figure this out but the holes on the top of the

wing where the wing walk doublers are get counter sunk and

thus use K1000 plate nuts. All the other holes are

dimpled and use K1100 plate nuts. (12/10/05) |

| |

E

Not much has happened to the wings since they were removed

from the fuselage. Last week the left wing was put on

sawhorses so I could install the plate nuts that hold the wing

root fairing in place. While I was at it I took care of

the service bulletin that requires removing the tank

inspection plate so the nut holding the fuel pickup tube could

be drilled and safety wired. Note the fuel pickup, it is

an options from Van's that not many builders seem to know

about. (03/08/07) E

Not much has happened to the wings since they were removed

from the fuselage. Last week the left wing was put on

sawhorses so I could install the plate nuts that hold the wing

root fairing in place. While I was at it I took care of

the service bulletin that requires removing the tank

inspection plate so the nut holding the fuel pickup tube could

be drilled and safety wired. Note the fuel pickup, it is

an options from Van's that not many builders seem to know

about. (03/08/07) |

| |

F

The fuel pickup tube service bulletin is complete.

Another local builder wrote the SB number and date of

compliance on the tank cover, which I thought was a great idea. (03/14/07) F

The fuel pickup tube service bulletin is complete.

Another local builder wrote the SB number and date of

compliance on the tank cover, which I thought was a great idea. (03/14/07) |

| |

E

With the fuel tank service bulletin complied with, I elected

to fill both tanks with 100LL and calibrate the Dynon D10 EMS.

I do not recommend you play with fuel in an enclosed basement

as there could be ignition sources there. In my case,

there are none, the furnace, hot water heater, etc. are all in

the garage. In addition, I had all the windows and doors

open along with fans to pull the fumes out. Still it

stunk the place up. On the good side, neither tank

leaked and the calibration was easy enough to do. (04/5/07) E

With the fuel tank service bulletin complied with, I elected

to fill both tanks with 100LL and calibrate the Dynon D10 EMS.

I do not recommend you play with fuel in an enclosed basement

as there could be ignition sources there. In my case,

there are none, the furnace, hot water heater, etc. are all in

the garage. In addition, I had all the windows and doors

open along with fans to pull the fumes out. Still it

stunk the place up. On the good side, neither tank

leaked and the calibration was easy enough to do. (04/5/07) |

| |

F

After installing the wing tips I noticed they did not line up

with where the ailerons should be. The solution is to

cut the trailing edge of the wing tip and down the side.

Push it into the correct position and fiberglass it up.

Not a big deal but just another time consuming task. (5/27/07) F

After installing the wing tips I noticed they did not line up

with where the ailerons should be. The solution is to

cut the trailing edge of the wing tip and down the side.

Push it into the correct position and fiberglass it up.

Not a big deal but just another time consuming task. (5/27/07) |

| |

E

Here I am driving the rivets Nora is bucking. (2/26/04)

E

Here I am driving the rivets Nora is bucking. (2/26/04) F

The weekend of March 21st, 22nd, & 23rd, 2004 Doug Sytsma, my

collage roommate, A&P, and Northwest Airlines Maintenance

Manager came down from Detroit to lend a hand pounding rivets.

In two days we finished riveting the left wing and started on

the right wing. (03/20/04)

F

The weekend of March 21st, 22nd, & 23rd, 2004 Doug Sytsma, my

collage roommate, A&P, and Northwest Airlines Maintenance

Manager came down from Detroit to lend a hand pounding rivets.

In two days we finished riveting the left wing and started on

the right wing. (03/20/04) E

Here it the left wing off the jig for the first time.

()3/20/04)

E

Here it the left wing off the jig for the first time.

()3/20/04) F

We even managed to assemble and match drill the right wing

during Doug's visit. Now all that is left is deburring,

dimpling, priming, and riveting. (03/21/04)

F

We even managed to assemble and match drill the right wing

during Doug's visit. Now all that is left is deburring,

dimpling, priming, and riveting. (03/21/04) E

Six days before the wedding and here is Nora helping rivet the

bottom skin on the right wing. At least she can't say

she didn't know what she was getting herself into. (09/06/04)

E

Six days before the wedding and here is Nora helping rivet the

bottom skin on the right wing. At least she can't say

she didn't know what she was getting herself into. (09/06/04) F

Last weekend

was spent cutting the left wing skin and fitting the Gretz

pitot tube mast, which is supposed to hold the Dynon pitot

tube. This pitot tube is configured to feed AOA information

to my future Dynon EFIS system. After cutting the wing skin,

drilling holes for the AOA line, etc. I test fitted the mast

and all looked good until I slid the pitot tube down the mast

and found the pre-drilled holes in the mast that are to hold

the pitot in place wouldn't leave any room for proper edge

distance on the pitot tube. I'm currently talking to both

Dynon and Warren Gretz about a solution. BTW, both the Gretz

mount and the Dynon unit seem to be top quality items and I do

expect there will be an easy resolution. (I smudged the

chrome pitot tube bracket so the flash wouldn't wash it out

.) (09/25/04)

F

Last weekend

was spent cutting the left wing skin and fitting the Gretz

pitot tube mast, which is supposed to hold the Dynon pitot

tube. This pitot tube is configured to feed AOA information

to my future Dynon EFIS system. After cutting the wing skin,

drilling holes for the AOA line, etc. I test fitted the mast

and all looked good until I slid the pitot tube down the mast

and found the pre-drilled holes in the mast that are to hold

the pitot in place wouldn't leave any room for proper edge

distance on the pitot tube. I'm currently talking to both

Dynon and Warren Gretz about a solution. BTW, both the Gretz

mount and the Dynon unit seem to be top quality items and I do

expect there will be an easy resolution. (I smudged the

chrome pitot tube bracket so the flash wouldn't wash it out

.) (09/25/04)