| |

| This section is definitely under

construction. |

| |

E

All I have done is spent an hour thinking about how I want my schematic to

look. I haven't vetted this with anyone yet but as soon as I do,

I'll post it for your viewing pleasure. Comments and thoughts are

welcome. (7/15/05) E

All I have done is spent an hour thinking about how I want my schematic to

look. I haven't vetted this with anyone yet but as soon as I do,

I'll post it for your viewing pleasure. Comments and thoughts are

welcome. (7/15/05) |

| |

F

The electrical system is set as good as it's going to be. Now is

time to start pulling wires. Some

things are still unknown, like the wire sizes required for the Emag/Pmag's.

Once I buy those things, I will adjust the size accordingly and update the

drawings. This is version 3.5, a lot of time went into this and I

highly recommend all builders take some time to work out there electrical

system before pulling wires. Especially first time builders like

myself. (1/8/06) F

The electrical system is set as good as it's going to be. Now is

time to start pulling wires. Some

things are still unknown, like the wire sizes required for the Emag/Pmag's.

Once I buy those things, I will adjust the size accordingly and update the

drawings. This is version 3.5, a lot of time went into this and I

highly recommend all builders take some time to work out there electrical

system before pulling wires. Especially first time builders like

myself. (1/8/06) |

| |

|

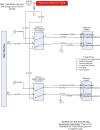

E

The amount of time I have put into designing the electrical system has

blown me away. At this point I have 18 hours logged on designing it

and I'm sure the actual amount of time is two or three times that.

These three pictures are final, I HOPE! I've ordered the switches

breakers and pull type circuit breakers from

Affordable Panels as they seem to have very competitive prices and I

really like their customer service. I've elected to go with

duel Pmag's over one Emag and one Pmag which settled the switch and wire

size issue. When designing your electrical system I highly recommend

buying the

Bob Knuckolls' AeroElectric book. It covers everything you will

need to know about homebuilt electrical systems and more. (2/11/06) E

The amount of time I have put into designing the electrical system has

blown me away. At this point I have 18 hours logged on designing it

and I'm sure the actual amount of time is two or three times that.

These three pictures are final, I HOPE! I've ordered the switches

breakers and pull type circuit breakers from

Affordable Panels as they seem to have very competitive prices and I

really like their customer service. I've elected to go with

duel Pmag's over one Emag and one Pmag which settled the switch and wire

size issue. When designing your electrical system I highly recommend

buying the

Bob Knuckolls' AeroElectric book. It covers everything you will

need to know about homebuilt electrical systems and more. (2/11/06) |

| |

F

Part of my electrical system will include two power ports AKA cigarette

lighter plugs. These are pictures of the duel plug unit I found at

West Marine. I like that they come with a face plate, plug covers,

and give you the option of mounting them in their own hole. One plug

will be switched with the avionics master and the other will be on the

"Always Hot" bus so I can use a trickle charger or plug a computer, cell

phone, or whatever into it without turning on the master. This

always hot plug will get a bit heavier wiring and circuit breaker to

handle that trickle charger. The little amber LED light in the right

picture will be used as a "Fuel Pump On" light and will be mounted high in

the panel so I can see it in my pre-takeoff scan and as a reminder should

I leave the fuel pump on after take off. Here is a picture of the

plugs fitted in the instrument panel. (2/11/06) F

Part of my electrical system will include two power ports AKA cigarette

lighter plugs. These are pictures of the duel plug unit I found at

West Marine. I like that they come with a face plate, plug covers,

and give you the option of mounting them in their own hole. One plug

will be switched with the avionics master and the other will be on the

"Always Hot" bus so I can use a trickle charger or plug a computer, cell

phone, or whatever into it without turning on the master. This

always hot plug will get a bit heavier wiring and circuit breaker to

handle that trickle charger. The little amber LED light in the right

picture will be used as a "Fuel Pump On" light and will be mounted high in

the panel so I can see it in my pre-takeoff scan and as a reminder should

I leave the fuel pump on after take off. Here is a picture of the

plugs fitted in the instrument panel. (2/11/06) |

| |

E

Yes, that is wires you see. Both power ports are now wired as is the

power lead for the position lights and fuel pump. A common ground

block is on order and once that is installed these wires will be

terminated at the firewall. Keeping the schematic close by at this

stage is very handy. As each wire is run and labeled the

corresponding circuit is checked off. (4/11/06) E

Yes, that is wires you see. Both power ports are now wired as is the

power lead for the position lights and fuel pump. A common ground

block is on order and once that is installed these wires will be

terminated at the firewall. Keeping the schematic close by at this

stage is very handy. As each wire is run and labeled the

corresponding circuit is checked off. (4/11/06) |

| |

F

Spent the day making the ground blocks, terminating some ground wires,

wiring up the flap motor, and thinking about the project. There are

20 tab connectors on the firewall side and 50 on the cabin side. The ground

blocks will be connected via a brass bolt. For now

an AN-5 bolt will hold things together until I procure a brass replacement. It sure felt good to

start terminating things on the ground block rather than just labeling

them and draping them over the firewall. Not to mention watching the

flaps motor up and down on command from the flap switch! (4/16/06) F

Spent the day making the ground blocks, terminating some ground wires,

wiring up the flap motor, and thinking about the project. There are

20 tab connectors on the firewall side and 50 on the cabin side. The ground

blocks will be connected via a brass bolt. For now

an AN-5 bolt will hold things together until I procure a brass replacement. It sure felt good to

start terminating things on the ground block rather than just labeling

them and draping them over the firewall. Not to mention watching the

flaps motor up and down on command from the flap switch! (4/16/06) |

| |

|

E

Like I actually thought I was finished updating these drawings in

February!? As I run wires I am making small changes, up sizing wire

sizes because I don't have any 16 AWG for instance, adding the flap switch

diagram, etc. I'll just use this paragraph to post my updated wiring

diagram. (4/16/06) Note - The drawings were updated once

again and I'm sure there are still inaccuracies in these drawings.

If you spot one, please let me know. (5/18/08). E

Like I actually thought I was finished updating these drawings in

February!? As I run wires I am making small changes, up sizing wire

sizes because I don't have any 16 AWG for instance, adding the flap switch

diagram, etc. I'll just use this paragraph to post my updated wiring

diagram. (4/16/06) Note - The drawings were updated once

again and I'm sure there are still inaccuracies in these drawings.

If you spot one, please let me know. (5/18/08). |

| |

|

F

Now it is time to start connecting the audio components of my panel.

A Sigtronics 200S stereo intercom will be the heart of the system.

An Apple iPod will be plugged into its stereo input jack. The GPS

outputs it terrain warnings through the 1/8" stereo output plug.

This means either the iPod or XM radio, not both. The

iCom

IC-A200 radio will be connected directly to the intercom, leaving three

items that need to be connected; the

Dynon EFIS D100,

Dyon EMS D10, and

Garmin GPS 396. The iCom radio has two audio input "ports" which can

be connected to two of these items so they can be played (heard?) through

the intercom. After posting a question regarding the

Dynon Smart Avionics Bus (DSAB) interconnectivity on the

Dynon Forum I found that the two units do not share audio output

function and that both units must be connect to the audio system.

However, Dynon did add that the audio out's from the two units could be

connected together. With the understanding that the 396 will "play"

through the stereo input, the two Dynon units will have their own input

channels on the radio. F

Now it is time to start connecting the audio components of my panel.

A Sigtronics 200S stereo intercom will be the heart of the system.

An Apple iPod will be plugged into its stereo input jack. The GPS

outputs it terrain warnings through the 1/8" stereo output plug.

This means either the iPod or XM radio, not both. The

iCom

IC-A200 radio will be connected directly to the intercom, leaving three

items that need to be connected; the

Dynon EFIS D100,

Dyon EMS D10, and

Garmin GPS 396. The iCom radio has two audio input "ports" which can

be connected to two of these items so they can be played (heard?) through

the intercom. After posting a question regarding the

Dynon Smart Avionics Bus (DSAB) interconnectivity on the

Dynon Forum I found that the two units do not share audio output

function and that both units must be connect to the audio system.

However, Dynon did add that the audio out's from the two units could be

connected together. With the understanding that the 396 will "play"

through the stereo input, the two Dynon units will have their own input

channels on the radio.

What is all this stuff trying to tell me? The EFIS will give audio

stall warning from the AoA port. The EMS will announce any out of

bounds condition regarding engine operation such as high or low oil

pressure, temperature, etc. The GPS can output terrain warnings and

XM radio signal. (4/18/06) |

| |

|

E

These pictures could go almost anywhere. What you are looking at is

the Outside Air Temperature (OAT) probe and its associated wire runs.

The OAT for the Dynon units connect at the remote compass. Thus, the

compass is required if you want to use the OAT. The only use for the

OAT is so the system can calculate True Airspeed. This location will

be covered by some fiberglass fairing. Even though it might heat up

with the aircraft on the ground, once it starts moving the tail section

will get fresh air and by the time I hit cruising altitudes I suspect it

will register correctly. This location was chosen in an effort to

protect the probe. Remember, this will be a tail dragger and there

is a chance it would get damage if placed under the HS. The tray

that will hold the remote compass is visible at the top of the second

picture. (The red strap is to keep my fuselage from tipping forward

when I climb in the cockpit.) (4/19/06) E

These pictures could go almost anywhere. What you are looking at is

the Outside Air Temperature (OAT) probe and its associated wire runs.

The OAT for the Dynon units connect at the remote compass. Thus, the

compass is required if you want to use the OAT. The only use for the

OAT is so the system can calculate True Airspeed. This location will

be covered by some fiberglass fairing. Even though it might heat up

with the aircraft on the ground, once it starts moving the tail section

will get fresh air and by the time I hit cruising altitudes I suspect it

will register correctly. This location was chosen in an effort to

protect the probe. Remember, this will be a tail dragger and there

is a chance it would get damage if placed under the HS. The tray

that will hold the remote compass is visible at the top of the second

picture. (The red strap is to keep my fuselage from tipping forward

when I climb in the cockpit.) (4/19/06) |

| |

|

F

After much questioning, searching and head scratching I discovered the

iCom radio has three mono inputs and the Garmin GPS outputs its terrain

warnings out through it 1/8" stereo jack. Thus the new design.

The only downside of this configuration is that the intercom 1/2 mutes the

stereo input when something is coming in over the radio. One thing

to keep in mind is that even though the radio and the signals going

through the radio are mono, they will be played in both left and right

channels. Also, modern intercom designs, such as the Sigtronics pass

through any radio signal when turned off or in failure mode. What

you wont be able to hear is the passenger. For a Day/Night VFR ship,

I do not consider this a safety issue. (5/1/06) F

After much questioning, searching and head scratching I discovered the

iCom radio has three mono inputs and the Garmin GPS outputs its terrain

warnings out through it 1/8" stereo jack. Thus the new design.

The only downside of this configuration is that the intercom 1/2 mutes the

stereo input when something is coming in over the radio. One thing

to keep in mind is that even though the radio and the signals going

through the radio are mono, they will be played in both left and right

channels. Also, modern intercom designs, such as the Sigtronics pass

through any radio signal when turned off or in failure mode. What

you wont be able to hear is the passenger. For a Day/Night VFR ship,

I do not consider this a safety issue. (5/1/06) |

| |

|

E

The wiring is so much fun! I have elected to use plate nuts wherever

possible to hold stuff. Here is a picture of the dimmer controller

over the transformer / converter for the

electroluminescent strips above the switch panels. They are held in

place with plate nuts and 8-32 cap screws. The cap screws are easier

to use, IMHO, and are much easier to install and remove than standard

Phillips head screws. These are mounted on the forward side of the

sub-panel. (8/23/06) E

The wiring is so much fun! I have elected to use plate nuts wherever

possible to hold stuff. Here is a picture of the dimmer controller

over the transformer / converter for the

electroluminescent strips above the switch panels. They are held in

place with plate nuts and 8-32 cap screws. The cap screws are easier

to use, IMHO, and are much easier to install and remove than standard

Phillips head screws. These are mounted on the forward side of the

sub-panel. (8/23/06) |

| |

|

F

Figuring out how and where to run wires is always a challenge

for every builder. This is a shot of the forward floor. Notice

how all the electrical and ground wires are running up the right side of

the fuel line and the radio antenna cable is running up the left side.

This, I hope, will help reduce noise in my transmissions. (8/23/06) F

Figuring out how and where to run wires is always a challenge

for every builder. This is a shot of the forward floor. Notice

how all the electrical and ground wires are running up the right side of

the fuel line and the radio antenna cable is running up the left side.

This, I hope, will help reduce noise in my transmissions. (8/23/06)

|

| |

|

E

These are just

some pictures of my wire mess. It is coming together and will be

straightened out before I close up the top skin. I was using twist

ties to hold the wires in the correct place and help keep it neat.

Using Adel clamps on the bottom of the ribs has been a great help.

If I run out of room in a clamp, it gets replaced with a larger one.

It can't get much simpler than that. (8/23/06) E

These are just

some pictures of my wire mess. It is coming together and will be

straightened out before I close up the top skin. I was using twist

ties to hold the wires in the correct place and help keep it neat.

Using Adel clamps on the bottom of the ribs has been a great help.

If I run out of room in a clamp, it gets replaced with a larger one.

It can't get much simpler than that. (8/23/06) |

| |

|

F

These are so

many options when it comes time to install the antennas. The

transponder antenna is located right behind the firewall on the right

side, next to the fuel vent. The com antenna is forward of the spar,

under the pilots left knee with the aft two #8 screws piercing the spar

flange. In retrospect, it might have been better to have put the com

antenna behind the firewall and the transponder antenna just in front of

the spar. One advantage of keeping everything forward of the spar is

that none of those thick cables have to go through the spar, which has

limited passages. The remaining hole, seen in this picture will be

used as the pass through for the pitot and AoA lines. F

These are so

many options when it comes time to install the antennas. The

transponder antenna is located right behind the firewall on the right

side, next to the fuel vent. The com antenna is forward of the spar,

under the pilots left knee with the aft two #8 screws piercing the spar

flange. In retrospect, it might have been better to have put the com

antenna behind the firewall and the transponder antenna just in front of

the spar. One advantage of keeping everything forward of the spar is

that none of those thick cables have to go through the spar, which has

limited passages. The remaining hole, seen in this picture will be

used as the pass through for the pitot and AoA lines.

Big news, right

after dinner I dragged Nora into the basement so we could try out the

electronics. As expected, the radio could transmit and receive, the

intercom worked, and so did the audio in jack for the stereo intercom.

The only thing left to test is the warning tones from the two Dynon units.

(9/1/06) |

| |

|

E

The ammeter

shunt was installed on the inside of the left forward rib, between the

sub-panel and the firewall. The small wires leading to this go to

the Dynon D10 EMS and the large wire from the contactor to the main bus

are yet to be installed. (9/17/06) E

The ammeter

shunt was installed on the inside of the left forward rib, between the

sub-panel and the firewall. The small wires leading to this go to

the Dynon D10 EMS and the large wire from the contactor to the main bus

are yet to be installed. (9/17/06) |

| |

|

Some times it is

the small things that help you feel like you are making real progress.

The thing that got me was finally connecting the master switch and "keep

alive" bus. No more running jumpers are required to play with the

instrument panel. Better yet, the cigarette lighter charger can now

be used to keep the battery fully charged. (10/1/06) |

| |

|

F

Today I had good

intentions of working on something else, any thing else, but my friend Rradomir called to say he connected his strobes and tried them out for the

first time. Much to his dismay, he could hear the strobe discharging

through his intercom and radio. Even though he used a different

strobe system than I, he connected his in the same way with the power and

wire shield grounds run forward to the main ground block located on the

firewall. After much rooting around he pulled the grounds back and

grounded both items together at the power supply. Upon returning to

my workshop, I thought now might be a good time to connect my strobes and

try them for the first time, as well. With headphones on, I turned

on the radio master and the flipped the strobe switch. Here is one

word of advice, close your eyes if standing next to the strobes.

Since my wings aren't on the strobes were connected right next to where I

was standing on the side of the fuselage. My eye sight is slowly

returning to normal. F

Today I had good

intentions of working on something else, any thing else, but my friend Rradomir called to say he connected his strobes and tried them out for the

first time. Much to his dismay, he could hear the strobe discharging

through his intercom and radio. Even though he used a different

strobe system than I, he connected his in the same way with the power and

wire shield grounds run forward to the main ground block located on the

firewall. After much rooting around he pulled the grounds back and

grounded both items together at the power supply. Upon returning to

my workshop, I thought now might be a good time to connect my strobes and

try them for the first time, as well. With headphones on, I turned

on the radio master and the flipped the strobe switch. Here is one

word of advice, close your eyes if standing next to the strobes.

Since my wings aren't on the strobes were connected right next to where I

was standing on the side of the fuselage. My eye sight is slowly

returning to normal.

Sure enough, you could hear the

strobe discharge through the headsets. After fabricating a ground

point (Angle aluminum and a plate nut riveted to the underside of the

baggage compartment floor.)

the noise went away for me as well.

I suspect the long ground wires

make a very nice antenna and by grounding the locally and removing the

"antenna", the problem went away.

The simple

drawing should give you a better idea of how I wired the strobe grounds. (11/21/06) |

| |

|

E

It was time to wire up the P-mags.

Not a difficult task but an important one. Remember, it is just your

ignition system you are messing with. This diagram lists how I wired mine, you may have different requirements. One change I

made was replace the ground service switch with a 1/8" stereo jack and plug,

this eliminated the need for

warning light since the plug will have red "Remove Before Flight" streamer

attached to it. Note, I originally installed a mono jack only to

find out that one side of the jack shorts to ground. This forced me

to change it to a stereo plug and jack. If you have a P-mag breaker

pop when you turn on the master, you are probably shorting to ground

through this plug arrangement. (6/17/07) E

It was time to wire up the P-mags.

Not a difficult task but an important one. Remember, it is just your

ignition system you are messing with. This diagram lists how I wired mine, you may have different requirements. One change I

made was replace the ground service switch with a 1/8" stereo jack and plug,

this eliminated the need for

warning light since the plug will have red "Remove Before Flight" streamer

attached to it. Note, I originally installed a mono jack only to

find out that one side of the jack shorts to ground. This forced me

to change it to a stereo plug and jack. If you have a P-mag breaker

pop when you turn on the master, you are probably shorting to ground

through this plug arrangement. (6/17/07) |

| |

|

F

The preflight procedure with P-mags wired as I have is different than a

standard aircraft and this must be taken into account prior to each

flight. The basics are that each P-mag should be operationally

verified as functional when running on both ship's power and internal

power. This diagram displays how I perform this preflight task.

(5/18/08) F

The preflight procedure with P-mags wired as I have is different than a

standard aircraft and this must be taken into account prior to each

flight. The basics are that each P-mag should be operationally

verified as functional when running on both ship's power and internal

power. This diagram displays how I perform this preflight task.

(5/18/08) |

| |